Undoubtedly the world has progressed manifold in terms of discovery and development. Several devices manufacture each day to make our lives easier. But a very significant part of this process is the practical assessment of its working and assembly. Thus meters and test equipment play a crucial role in inspecting defects, testing the functionality, accuracy, and responsiveness of the device. Most manufacturers have the ultimate goal of providing innovative solutions contributing to the efficiency, profitability, and quality of their customers. In the laboratory, diverse instruments are required for monitoring & measuring relative humidity, temperature, dew point, airflow, and oxygen level and other particles. If you happen to have questions about the advantages of “using testing equipment and meters “, read along to find the answers to make the right choices for your device.

Advantages of testing equipment and smart meters

Utilizing the right equipment for testing instruments in real and simulated forms is the key criteria for enhancing the credibility of your work. Let’s look into the benefits of this equipment.

Validating performance: Over time, the parts of any device wear out due to continual usage. They degrade and become outdated owing to its exposure to temperature, shocks, vibration, etc. regularly. With the help of testing equipment, a technician performs routine maintenance to ensure consistency and track the performance of the device. Keeping a track record of how the instrument executes its functionality frequently will enable us to fix the flaws.

Objectivity goals: The prime objective of any device is its functionality and how well does it fulfill its operation. Meters & Test Equipment keep a check on whether the sample meets the minimum standards of work. The first step of any controlled experimentation is to obtain the data like humidity levels, the proportion of oxygen required, and particulate concentration, etc. with the help of meters and data analogs. Then the data acquired is verified and monitored with testing equipment to check the authenticity. Samples are examined over a longer time so that the final product of the task is fruitful.

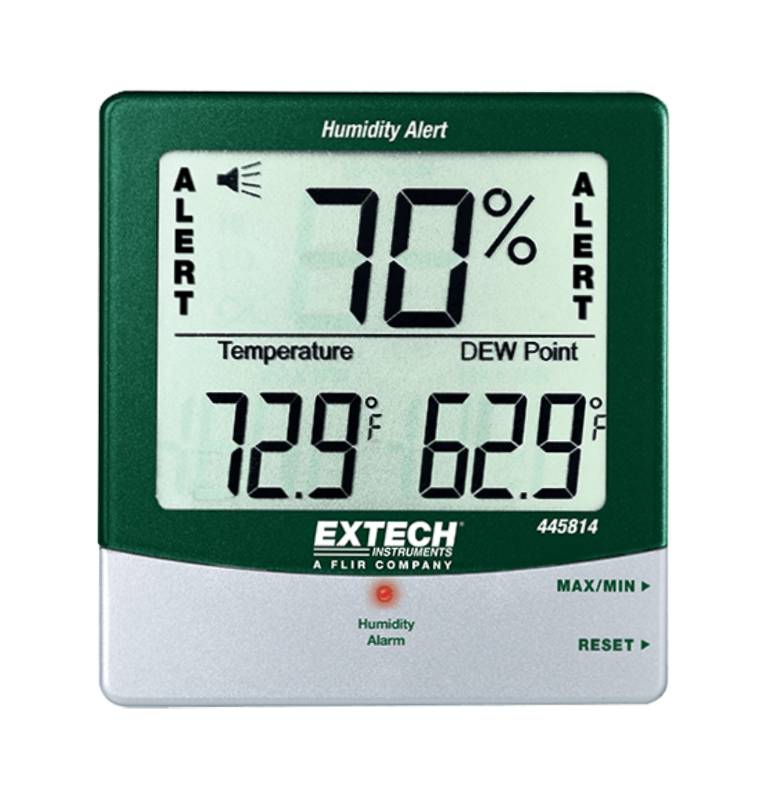

Preciseness: Testing not only examines the objectivity of an experiment but also allows information to flow for several basic parameters with accuracy. The most foremost principle of a device/ sample is how correctly it works. The meters give accurate results with minimal errors. Usually, there are digital meters that do not need manual monitoring and calculation, thereby displaying the results directly on the screen. This precise information is significant for conducting research and improves the chances of success while executing an experiment in the lab.

Ease of use: To estimate the number of particulate matter in a sample or observing relative humidity without equipment is difficult. It would not only result in experimental errors but make the task strenuous. Testing equipment alleviates the concerns regarding data interpretation and collection. Our task now becomes easy; all we need to do is monitor the device periodically for optimum results. With scientific advancements, people always prefer to go for handy solutions rather than the longer route.

Economic concerns: A failed experiment not only disappoints but is a huge concern from the financial side. Manufacturers would never like to produce and market a faulty product that cannot deliver its services to the customers. Likewise, a failed laboratory experiment is a setback for a technician. All the money and time invested goes in vain. Thus it is better to test the samples with appropriate testing equipment at each stage for a successful output. That would deliver accuracy and quality to the task done.

Chances of improvement: It is advisable to monitor the parameters of a sample. That would prompt any irregularities in the task performed and correct within the right timeframe. Testing equipment and meters detect any faults in the sample or testing environment and provides chances of improving them to enhance productivity. It is necessary to make amendments to the concentration or any configuration of a sample. An improved version of the product helps in enhanced manufacturing and marketing.

Quality check: For successful experimentation, the meters and testing equipment verify the quality of a sample. Sometimes, inadequate quality produces unlikely results that hinder the final output. It is best to cross-check and examine parameters beforehand for reliable and uninterrupted functioning.

Safety: While working in the laboratory it is essential to be cautious about every parameter that is controlled for a specified experiment. An increase or decrease in its level may trigger an explosive reaction and is unsafe for the laboratory experts. Thus it is important to keep a regulatory check by using testing meters to deliver safe results and prohibit any untoward incident.